Home Page

Contact us

Services

Products

Installations

Projects

Need a Quotation !

Quotation !

Clients

Links

|

Techinical Information

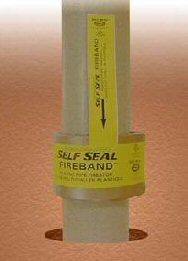

SELF SEAL® FIRESTOP SELF SEAL® FIREBAND

Intumescent Silicone Firestop Wrap Strip That Protects Your Wall

and Floor Openings

"Tested at positive pressure to simulate the pressure differentials that

can occur in a fire situation"

PRODUCT:

SELF SEAL® FIREBAND is an intumescent silicone rubber wrap strip encapsulated within a poly bag and is designed to seal combustible pipe penetrations in fire-rated walls and floors. The wrap strip is tightly wrapped around the combustible pipe and held in place with an adhesive strip on the bag. The silicone composition exhibits excellent performance stability and when exposed to temperatures in excess of 300OF (150OC) it will begin to expand. As the pipe softens and collapses under fire conditions, the silicone composition will rapidly intumesce to fill the void with a patented char composite that contains expanded graphite. The wrap strips are pre-fabricated to fit 1-1/2” (38 mm), 2” (51 mm) and 3” (76 mm) trade sized pipes.

SELF SEAL® FIREBAND can be used to firestop solid core Polyvinyl Chloride (PVC) vented and Chlorinated Polyvinyl Chloride (CPVC) sprinkler pipe penetrations. Drain, waste and vent pipe penetrations firestopped with SELF SEAL® FIREBAND meet the Canadian building code test requirement for a pressure differential of 50 Pa between the exposed and unexposed sides of concrete, wood floor-ceiling and drywall fire separations.

SELF SEAL® FIREBAND is also in compliance with the 3rd edition of ANSI / UL1479 “Fire Tests of Through Penetration-Firestops”, to be effective May 23, 2006, for the following environmental exposure tests: Accelerated Aging; High Humidity; Industrial Atmosphere (SO2 and CO2) and Combination Wet, Freeze and Dry Cycling.

FEATURES AND TYPICAL USES:

SELF SEAL® FIREBAND seals combustible pipe penetrations through fire and smoke rated wall and floor separations. See MECHANICAL and ELECTRICAL APPLICATION CHARTS for details.

INSTALLATION:

• All substrates must be clean and sound; free of oil, frost, grease, dust, and other foreign materials.

• Select the wrap strip to fit the diameter of the pipe to be firestopped. The wrap strip is tightly wrapped

around the pipe and held in place with an adhesive strip provided on the bag. The wrap strip is then slid into the opening and positioned as specified in the firestop system listing. The annular space between the pipe / wrap strip / periphery of the opening is then sealed with SELF SEAL® GG-200 or GG-266 in accordance with the firestop system listing. Wrap strips are applied on both sides of wall penetrations and certain floor assemblies. See APPLICATION GUIDELINES for further details.

SELF SEAL® FIREBAND is only recommended for use in firestop systems that are listed in either the UL Fire Resistance Directory Vol. 2 or UL Directory of Products Certified for Canada.

TYPICAL PROPERTIES:

Supplied:

Specific Gravity: 1.26 – 1.29

Free Expansion Volume: > 9 times original volume when heated at 662OF (350OC)

*THESE VALUES ARE FOR GENERAL INFORMATION AND NOT FOR SPECIFICATION PURPOSES

SPECIFICATIONS:

SELF SEAL® FIREBAND meets ASTM E-814, ANSI / UL1479, UBC 7-5 and ULC-S115.

ORDERINGINFORMATION:

* Pre-fabricated wrap strips to fit 1-1/2” (38 mm), 2” (51 mm) and 3” (76 mm) trade sized pipes.

WARRANTY:

The company warrants that each quantity of SELF SEAL® FIREBAND product delivered will be of the kind designated or specified by it and no other warranty (except of title) is implied.

Return to:

Self Seal Products

All Products

© Copyright 2012 All rights reserved www.globalfirestopservices.com

Designed and Maintained by: John Smillie/Lasting Impressions

|