Home Page

Contact us

Services

Products

Installations

Projects

Need a Quotation !

Quotation !

Clients

Links

|

TECHNICAL INFORMATION

NUFLEX 3 0 9 CONCRETE METAL & VINYL SEALANT

NuFlex 309 Building Sealant is a one-part, neutral-cure elastomeric silicone sealant that cures to form a durable, flexible, low modulus sealant that is compatible with common building materials.

NuFlex 309 Building Sealant is a one-part, neutral-cure elastomeric silicone sealant that cures to form a durable, flexible, low modulus sealant that is compatible with common building materials.

FEATURES AND TYPICAL USES:

NuFlex 309 is particularly effective for sealing construction joints suchas those found in precast concrete, curtainwall and mullion joints. It forms a durable, flexible, watertight bond with most building substrates in any combination: masonry, ceramics, galvanized steel, aluminum and most plastics. It is virtually unaffected by ultraviolet radiation, ozone, airborne chemicals or extreme temperatures.

SURFACE PREPARATION AND APPLICATION:

All surfaces must be dry and frost-free, free of oil, grease, rust, dirt or other contaminants that may inhibit proper adhesion. For porous substrates, such as concrete, wire brushing or air blasting (oil-free) is

recommended and for non-porous substrates, a solvent wipe (oil-free) is adequate. Most substrates do not require a primer before application of the NuFlex 309 sealant. It is recommended, however, that test samples of sealant be applied to the surface to test and verify adhesion. After preparatory work is complete, mask where necessary to avoid spillage onto adjoining surfaces. Tooling should be done immediately after sealant is applied and in one continuous motion. Masking Tape

should be removed immediately after tooling is completed.

Limitations: NuFlex 309 should not be applied below grade, to surfaces under continuous water immersion, to substrates that bleed oils, plasticizers or solvents (e.g. impregnated wood, oil-based caulks, green or partially vulcanized rubber gaskets or tapes), to surfaces in direct contact with food, and to surfaces that will be painted over.

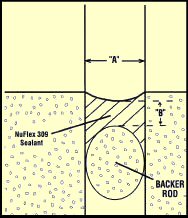

Joint Design: For maximum sealant performance, the following joint design principles should be applied. A backer rod will: (1) ensure adequate backpressure during extrusion of the sealant which will provide good substrate wetting and adhesion (2) eliminate the possibility of three-sided adhesion and (3) control the depth of the sealant. The joint should be tooled concave to form the illustrated hour-glass shape which will accommodate any sealant bulge during compression. The joint width ("A") and sealant depth ("B") should not be less than 6.4 mm (1/4"). For joint widths in excess of 6.4 mm (1/4"), the depth of the sealant ("B") should be equal to one half of the joint width ("A"). For joint widths in excess of 25.4 mm (1"), the depth of the sealant ("B") should not exceed 12.7 mm (1/2").

CAUTIONS:

CAUTIONS:

Use in well ventilated areas and avoid breathing vapors. On contact, uncured sealant irritates eyes. Flush eyes with lukewarm water. Call physician. Avoid skin contact and do not ingest. Keep out of reach of

children. For complete safety information consult Material Safety Data Sheet.

SPECIFICATIONS:

NuFlex 309 complies with ASTM C 920, Type S, Grade NS, Class 25, Use NT, M, G, A, O and CAN/CGSB-19.13-M87, Class MCG-2-40-A-L.

PACKAGING AND COLOURS:

Nuflex 309 Metal & Vinyl is available in a variety of sizes 300 ml (10.1 U.S fl oz), 850 ml (28.6 U.S. fl oz) all-plastic caulking cartridges with nozzle which fit manual or air operated caulking guns, (12 cartridges to a case). 10 litre (2.6 U.S. gallon) pails, 17 litre (4.5 U.S. gallon) pails and 200 litre (52 gallon) drums. Nuflex 309 Metal & Vinyl is available in a wide variety of colours, white, black,bronze, natural stone and grey. Special colours are available in orders of minimum quantities upon request. For sealant coverage or yields please see the “Coverage Chart” found in the “Application tip” section of the Nuco technical binder.

SHELF-LIFE AND STORAGE:

Shelf-life is 12 months from date of shipment from our plant when stored in clean, dry area with temperature between 40°F to 90°F (4°C to 32°C).

WARRANTY INFORMATION:

NUCO Inc., warrants only that it’s product will meet it’s specifications. NUCO shall in no event be liable for incidental or consequential damage. NUCO’s liability, expressed or implied, is limited to the stated selling price of any goods found to be defective.

TYPICAL PROPERTIES:

These values are not intended for use in preparing specifications. Spec Writers, please contact NUCO Inc. before writing specifications if any further information is required.

As Supplied

Type one part silicone sealant

Cure Method neutral, moisture cure

Specific Gravity 1.12

Working Time at 25°C (77°F) and 50% R.H. - in minutes 5

Full Cure/Adhesion Time at 25°C (77°F) at 50% R.H. 14 – 21 days

As Cured

50% Modulus (ASTM D 412) MPa(psi) 0.21 (30)

100% Modulus (ASTM D 412) MPa(psi) 0.31 (45)

Tensile Strength (ASTM D 412) MPa(psi) 1.53 (200)

Elongation (ASTM D 412) 700%

Tear Strength (ASTM D 624, die ‘C’) 6.1 (35)

Hardness (ASTM C 661, Shore A) 20

Joint Movement Capability +/-50%

The information and data contained herein is BASED ON INFORMATION WE BELIEVE TO BE RELIABLE. Please read all statements, recommendations or suggestions herein in conjunction with our CONDITIONS of SALE which apply to all goods supplied by us. We assume no responsibility for the use of these statements, recommendations or suggestions, nor do we intend them as recommendation for any use which would infringe any patent or copyright.

Return to:

Self Seal Products

All products

© Copyright 2012 All rights reserved www.globalfirestopservices.com

Designed and Maintained by: John Smillie/Lasting Impressions

|